28H 1.8° Planetary Gear Stepper Motor

Nema11(28mm)

2

| Availability: | |

|---|---|

| Quantity: | |

Product Description

Henghe Hybrid Stepper Motors matched with High Precision Planetary Gearboxes are perfect for applications that require higher torque. Available in multiple popular gear rations including 5:1, 10:1, 20:1, and 50:1.Stepper Motor with Planetary or Spur Gearbox, Low speed, high torque.

The stepping motor is used in low-speed occasions---the speed does not exceed 1000 revolutions per minute, (6666PPS at 0.9 degrees), preferably between 1000-3000PPS (0.9 degrees), and it can be used here by a decelerating device. At this time, the motor has high working efficiency and low noise;

The stepping motor is best not to use the full-step state, the vibration is large in the full-step state;

The voltage value in the motor specification is not the driving voltage volt value. The specific driving voltage can be selected according to the stepper driver (recommendations: 42 and below motors use 12-24V, 57 motors use DC 24V-48V, 86 use DC 48-80V, 110 motor adopts higher than DC 80V)

For loads with large moments of inertia, a large frame size motor should be selected.

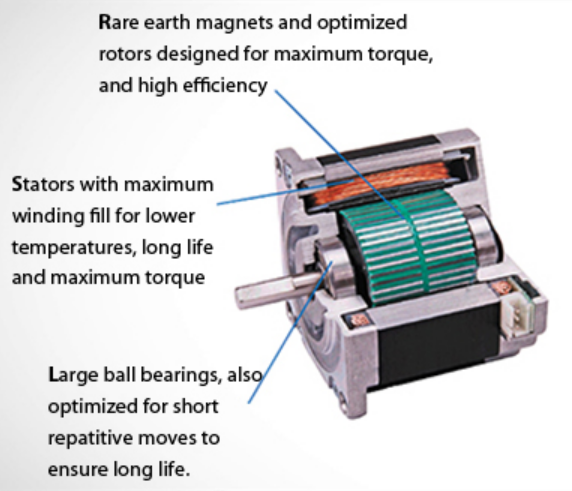

High torque is mainly attributed to many factors including rare earth magnets, optimized rotors, Stators with maximum winding fill and laminatins, all of which are combined together to realize maximum torque. Henghe Motor high torque stepper motors provide 15% to 25% more torque across the entire speed than conventional motors. The increased torque is a result of higher motor efficiency, and is available without increasing the drive voltage or current.

The design of Henghe Motor selected with new materials gets a lower resistance value when compared with motors of the same thickness and the same torque, this makes a greater degree of improvement for the thermal conductivity performance of the motor, thus greatly reduces the temperature rise of the motor.

Step motor life is usually determined by the life of the bearings. Henghe Motor large ball bearing is optimized for short repatitive moves to ensure long life - generally 5 times longer than conventional motors, which means future huge cost saving of the replacement or repair of conventional motors. In typical industrial application, the MTBF (Mean Time Between Failures) of Henghe Motor was up to 406,500 hours and lp (Failure Rate) was 3.44 hours per 1000,000 hours, In typical commercial application, the MTBF (Mean Time Between Failures) of Henghe Motor was up to 1,123,600 hours and lp (Failure Rate) was 1.21 hours per 1000,000 hours, which significantly ahead of competitor's motors.

Improved manufacturing processes enable all components of Henghe stepper motors to achieve better matching precision and more stable internal structures. This reduces vibration and noise effectively when the motor operates, which makes Henghe stepper motors stand out by providing quieter and smoother operation.

A stepper motor rotates with a fixed step angle, just like the second hand of a clock. This angle is called "basic step angle." Henghe Motor offers several types of "basic step angle" as standard motors: 2-phase stepping motors with a basic step angle of 0.9° and 1.8° and 3-phase stepping motors with a basic step angle of 1.2°.

Besides the standard motor, Henghe Motor also has stepper motors avalible with other "basic step angle." They are 0.72°, 1.5°, 3.6° and 3.75°, these motors are not listed in this catalogue, please contact Henghe Motor for details.

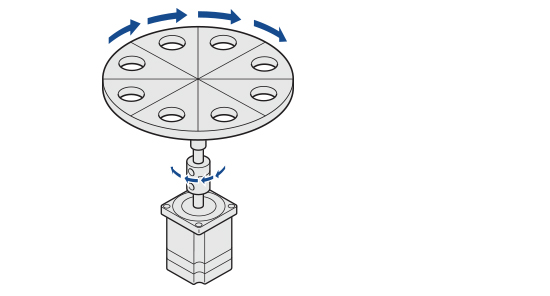

A system configuration for high accuracy positioning is shown below. The rotation angle and speed of the stepping motor can be controlled accurately using pulse signals from the controller.

A pulse signal is an electrical signal whose voltage level changes repeatedly between ON and OFF. Each ON/OFF cycle is counted as one pulse. A command with onepulse causes the motor output shaft to turn by one step. The signal levels corresponding to voltage ON and OFF conditions are referred to as "H" and "L," respectively.

The length of rotation of the stepping motor is proportional to the number of pulse signal (pulse number) given to the driver.The relationship of the stepper motor's rotation (rotation angle of themotor output shaft) and pulse number is expressed as follows:

The speed of the stepper motor is proportional to the frequency of pulse signals given to the driver. The relationship of the pulse frequency [Hz] and motor speed [r/min] is expressed as follows:

Stepper motors generate high torque with a compact size. These features give them excellent acceleration and response, which in turn makes these motors well-suited for torque-demanding applications where the motor must be started and stopped frequently. To meet the need for greater torque at low speed, Henghe Motor also has geared motors option.

Frequent Starting/Stopping is Possible

Stepper motor has full torque at stand-still as long as the windings are energized. This means that the motor can be held at a stopped position without using a mechanical brake.

Once the power is cut off, the self-holding torque of the motor is lost and the motor can no longer be held at the stopped position in vertical operations or when an external force is applied. In lift and similar applications, an electromagnetic brake type motor is required.

| Ring material | metal | |||

| Bearing at output | Ball bearings | |||

| Max. Radial load(10mm from flange) | 100N | |||

| Max. shaft axial load | 50N | |||

| Radial play of shaft(near to flange) | ≤0.07 mm | |||

| Axial play of shaft | ≤0.3 mm | |||

| Model | Voltage | Current | Resistance | Inductance | Maximum static | torque | Leader | Weight | Body length | Max. Gear Ratio |

| Single shaft A, double shaft B | V | A | Ω | mH | Oz- in | g.cm | Kg | L1(mm) | ||

| 28H32-0956A(B) | 2.66 | 0.95 | 2.8 | 1 | 6 | 430 | 6 | 0.11 | 32 | ≤1:189 |

| 28H32-0674A(B) | 3.8 | 0.67 | 5.6 | 4.2 | 8.3 | 600 | 4 | 0.11 | 32 | ≤1:189 |

| 28H45-0956A(B) | 3.2 | 0.95 | 3.4 | 1.2 | 10.4 | 750 | 6 | 0.14 | 45 | ≤1:189 |

| 28H45-0674A(B) | 4.6 | 0.67 | 6.8 | 4.9 | 13.2 | 950 | 4 | 0.14 | 45 | ≤1:189 |

| 28H51-0956A(B) | 4.4 | 0.95 | 4.6 | 1.4 | 12.5 | 900 | 6 | 0.2 | 51 | ≤1:189 |

| 28H51-0674A(B) | 6.2 | 0.67 | 9.2 | 5.7 | 16.7 | 1200 | 4 | 0.2 | 51 | ≤1:189 |

| Reduction ratio | 3.71 | 5.18 | 14 | 19 | 27 | 51 | 72 | 100 | 139 | 189 | 264 | 369 | |

| Accurate Reduction Ratio | 63/17 | Nov-57 | 3969/289 | 3591/187 | 3249/121 | 250047/4913 | 226233/3179 | 204687/2057 | 185193/1331 | 538861/2857 | 1119000/4243 | 3661450/9929 | |

| Number of gear trains | 1 | 2 | 3 | 4 | |||||||||

| Length(L2) | mm | 29 | 36.1 | 43 | 49.9 | ||||||||

| Max. rated torque | kg.cm | 12 | 20 | 40 | 40 | ||||||||

| Efficiency | % | 90% | 81% | 73% | 66% | ||||||||

| Backlash at no-load | 0.6° | 1.0° | 1.5° | 1.5° | |||||||||

| Weight | g | 75 | 97 | 119 | 141 | ||||||||

If this motor do not match with your request. Please feel free to contact with us,We can make customized shaft / winding / mounting flange / cable / connector.We will works side-by-side with you and your team to design a motor that will fit the precise needs of your application. All Engineering and Support is done in-house.

Henghe stepper motor is our best-selling stepper motor for numerous reasons: it delivers unbeatable balance between high performance and low price; it offers a high range of customizations; and its wide performance range makes it ideal for many applications.

Henghe stepper motor is a good fit for wide range of applications. The series is available in many stator lengths, from 1.34” (34mm) to 2.34” (59.4mm). Holding torque ranges from 44 oz-in (0.3 Nm), up to 115 oz-in (0.88 Nm). High range of dynamic torque with speed up to 1200 RPM. And a large selection of windings to meet your specific requirements.

Every component and every motor that leaves our facility must meet our mean value control. Additionally, every motor is tested to meet the required electrical specifications (resistance, inductance, leakage), torque specifications (holding and detent torque), mechanical specification (front shaft extension dimension and overall body length), and any other special feature specification. We want to ensure that your motor delivers the precise specifications you require. This gives you confidence that your motors will perform consistently and reliably within your application.

● Speed can be easily determined and controlled by remembering that speed equals steps per revolution divided by pulse rate.

● A stepper motor can make fine incremental moves.

● A stepper motor doesn’t require encoder feed back (Open loop).

● Non-cumulative positioning error.

● Excellent low speed/high torque characteristics without gear reduction.

● Holding torque of the stepper motor can be used to hold loads in stationary position without over heating.

● Ability to operate on a wide speed range.

Our motors are designed for quiet operation. This is achieved through our proprietary motor design techniques and material selection. There are many factors to consider, such as how the motor is mounted in the application and the load and speed at which the motor will operate. Another consideration is the type of bearings selected for the motor and/or gearmotor. Before making a final selection, the motor/gearmotor being considered should be thoroughly tested in the design for audible noise levels if this is a concern for the application.

A closed loop controller provides feedback from the motor response after a command is issued to ensure that the motor conducts the desired response, and an open loop controller issues commands with no feedback.

Our stepper motors are rated for a case temperature of 80 degrees C, which will be hot to the touch, but will not hurt the motor.

We recommend a torque safety margin of at least 30%.

Most stepper motors are designed for low speed (3000 rpm or less) operation. Once you get into higher speeds, servo motors are typically used.

Brakes hold the motor shaft in place by locking its position around the motor shaft. A brake cannot be used to slow the motor shaft.

We suggest you to order a sample. Also, you can send us email for detail photos for checking if you cannot get enough information in the product page.

Our price is the factory price, and if your quantity is larger, we will allow the discount for you.

Yes ,welcome warmly.